Klippenstein Corporation

Case and Tray Formers

Case and tray formers are essential to the overall packing process, and are often the first step in your automated packaging process. Our case formers and tray formers will remove the need for manual case or tray building, and can function at speeds between 15 to 35 trays per minute, depending on the model being used.

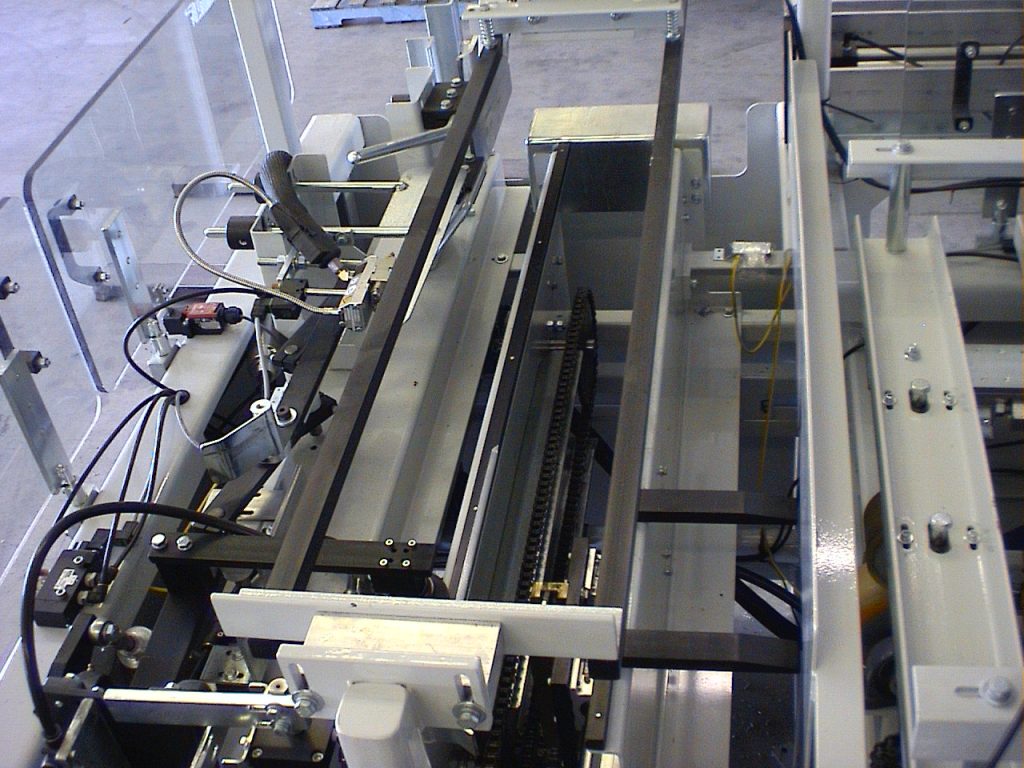

KF806HM - Tray Former

- Up to 35 trays/minute per lane

- Open tray – with or without minor and major flaps for top sealing

- Vertical Hopper with up to 30″ hold capacity

- Hot Melt System

- Safety Shield with Safety Sensors

- 80PSI Air Prssure with 1/2″ Diameter air Line

- 240 Volt/3 Phase/60Hertz

- Legend Plate Circuit Identification

- PLC (Programmable Logic Control)

- Touch Screen Controls

- Powder Coating & Zinc Plating on all wear surfaces

- Continues Run Mechanical Mandrel

- Run on Demand Photo Eye

- Training & Setup (Travel Expenses – additional)

- Single Lane verses Dual Lane

- Stainless Steel Construction w/Nema 4 Electrical Panel

- Casters with Locking Pads & Fork Lift channels

- Inner Fold Over flap

- 480 Volt – Main Power

- Spare Parts Kit

KF804HM - FOL Case Former

- Up to 12 cases/minute

- 216″L x 60″W x 55″ KD Stack Height

- 50# Almond Box (FOL) – Shown

- Top & Bottom Power Pinch Wheels, Blank Transfer

- X-Y Axis Vacuum Pick Case Indexing System

- 240 VAC / 3 Ph / 60Hz

- Chain Driven Pusher Bar Case Transfer

- Heavy Duty Pneumatic Case Forming Mandrel

- Powered Side Belt Case Compression

- Powder Coating & Zinc Plating on all wear surfaces

- Hot Melt System

- PLC (Programmable Logic Control)

- Touch Screen Controls

- Eye Sensors

- Auto run photo eye

- Pallet Staging Roller Conveyor W/heavy support frame

- Training & Setup (Travel Expenses – additional)

- Auto Lubrication System

- 480 Volt – Main Power

- Spare Parts Kit

KF8003HM - RSC Case Former

- Up to 15 cases/minute

- Pallet Unload Hopper with 48″ Pallet Height Capacity

- Creates manufactures seam and then erects

- Top & Bottom Power Pinch Wheels Blank Transfer

- X-Y Axis Vacuum Pick Case Indexing System

- 240 VAC / 3 Ph / 60Hz

- Chain Driven Lug, Case Transfer

- Heavy Duty Pneumatic Case Forming Mandrel

- Top & Bottom Pinch Wheels Manufactured Seam Compression

- PLC (Programmable Logic Control)

- Touch Screen Controls

- Powder Coating & Zinc Plating on all wear surfaces

- Hot Meld Adhesive Unit

- Full Safety Shields with Sensors

- E-Stop Air Dump

- Training & Setup (Travel Expenses – additional)

- Auto Lubrication System

- 480 Volt – Main Power

- Spare Parts Kit

How Do Case and Tray Formers Work?

Our Case Formers and Tray Formers will take flat pieces of cardboard that have been precut and printed by your preferred box supplier, and then quickly formed into a case or tray. Cases will be boxes that have top flaps to be sealed once packed, while trays are open on the top so that product may be loaded, but there is no final seal applied.

From here, the case or tray can easily be moved to your case packing system for automated packing, and then on to a case sealer for a complete solution that covers forming, filling, and sealing. Our Case Formers and Tray Formers can easily be integrated into any existing packaging line, allowing for streamlined production.

Industries That Use Case and Tray Formers

Case and tray formers are used in many different industries. The most common industry for them is the food industry, including nuts, dairy, proteins, grain, rice, beverages. They are used to produce the packaging for everything from cereal boxes to potato chip bags. In addition, it ensures your products have uniform packaging sizes. They are commonly utilized in the pharmaceutical industry as well to produce uniform packaging for the products. This helps ensure each product gets appropriately packed and shipped without damage.

When you want to make sure your products have uniform packaging sizes, use a case or tray former.

Customize the Packaging Equipment for Your Needs

Don’t worry if you’re not sure which type of case or tray former is best for your business. We can help you customize the packaging equipment to fit your specific needs.

We have a wide range of case formers and tray formers that can be adapted to package various products in different shapes and sizes. Plus, we have a team of experts that can help you design and configure the perfect packaging line for your business.

If you’re ready to improve your product packaging, contact us today to learn more about our case and tray formers.

Klippenstein Corporation is proudly powered by WordPress