Description of Machine…….

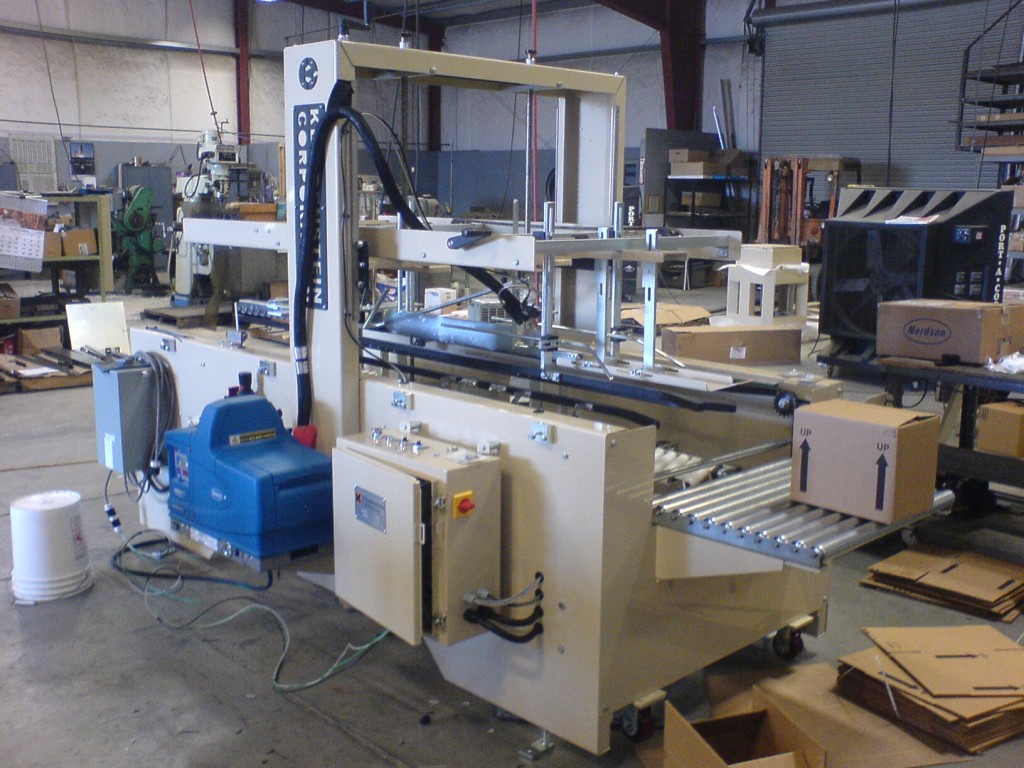

Designed and engineered for closing and sealing RSC cases containing pliable or rigid products. This model is built for semi-auto operation, which requires an operator to tuck in the top minor flaps and to push in the box into the machine. The machine is equipped with vertical crank screw adjust and horizontal ratchet slider adjust for quick change over. Also equipped with motorized chain driven flight bar for reliable caseadvance operation. Up to 15 Case per Minute performance.

Industries who have used this model include…….

Aerosol Cans, Cleaning Supplies and Walnuts

|

Standard Features |

Optional Features |

| Machine Performance: Up to 15 CPM. 105-1/2″ L x 54″ W |

Hot Melt or Tape Head |

| Machine Safety: 1/2″ Lexan Shields and Fully Guarded Pinch Points |

Random Case Height and Width |

| Power Req: 240VAC / 3 Phase / 60 Hz. |

Safety shield interlock switches |

| Drive Shafts: Stainless Steel, Precision Ground Shafts |

480VAC / 3 Phase/ 60Hz |

| Adjustibility: Crank screw adjust for height and ratchet slider adjust for width. |

Automatic lubrication system |

| Case Advance: Heavy Duty Flight Bar |

Corrosion resistant construction |

| Automatic Indexing and Rear Minor Flap Folding |

Case Sizes outside of Standard Range |

| Corrosion Protection: Powder coating and zinc plating on all surfaces. |

Corrosive resistant construction |

| Standard Case Range:Minimum: 7″L x 6″W x 6″HMaximum: 18″L x 15″W x 15-1/2″H |

Spare Parts Kit |